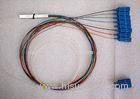

High Precision Fiber Optic LC Connector , Single Mode Fiber Connectors

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High Precision Fiber Optic LC C

High Precision Fiber Optic LC Connector , Single Mode Fiber Connectors

Quick Detail:

-

Compliant with the RoHS Directive

-

Low insertion loss, high return loss, easy to operate and save time

-

Based on the pluggable non-preset tube technology

-

Precision ceramic components with co-axial self centering, excellent and durable optical property

-

Always keeps connecting under the force from cabling and drawing

Applications:

FTTx

Rebuilding the wiring in optical equipment room

Specifications:

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Sunyking Technology Co., Ltd, [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)